To meet the most demanding needs of refractory producers, Alteo has redesigned its products, and launches the new range REal®.

To meet the most demanding needs of refractory producers, Alteo has redesigned its products, and launches the new range REal®.

Discover its advantages through the new brochure.

High-performance refractory materials are found in many industries: iron and steel making, cement, glass, non-ferrous metals,…

They have two main purposes: ensure the proper completion of the manufacturing process and improve the quality of the finished products.

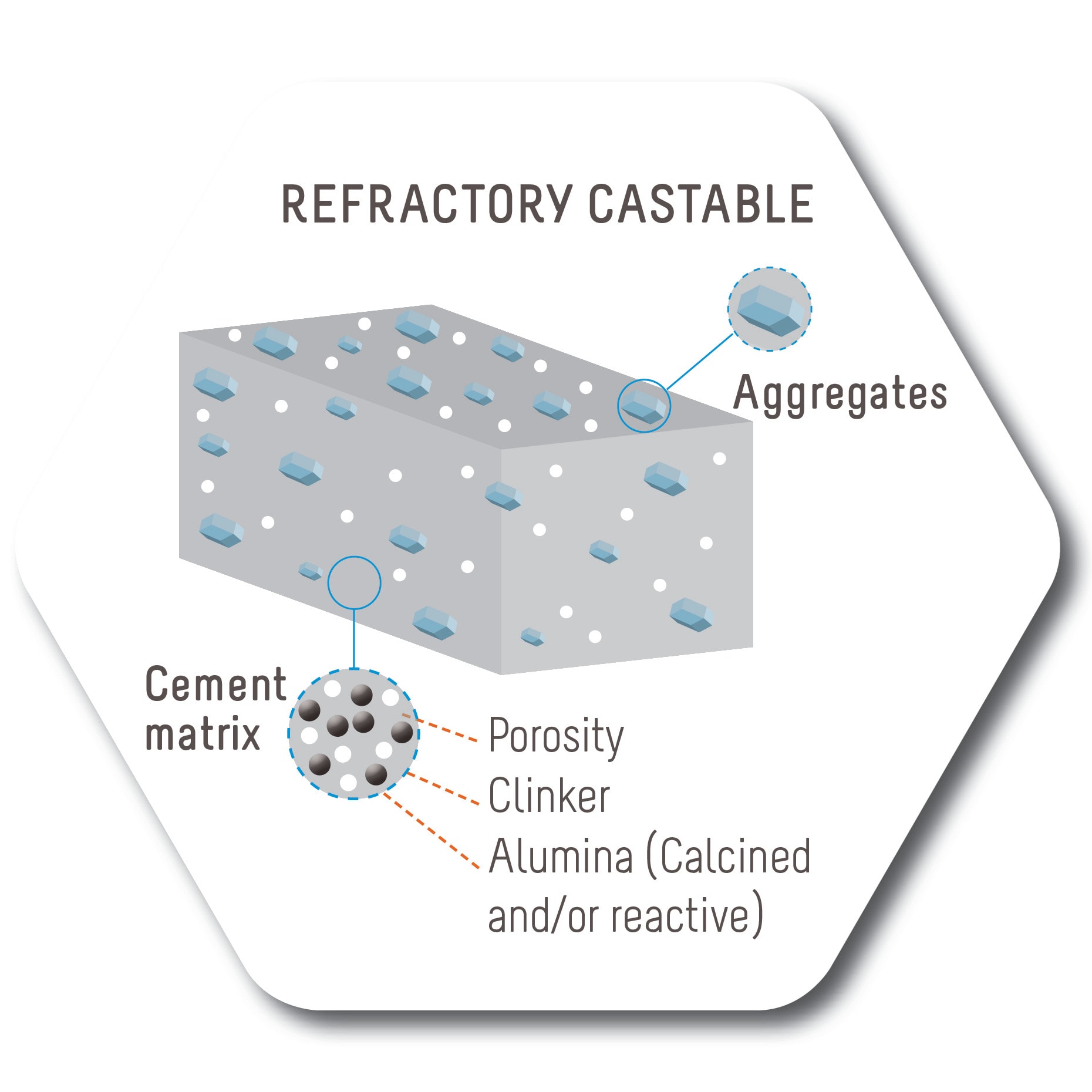

A typical refractory material is composed of four distinctive phases: aggregates, additives, binders and porosity. Binders, additives &porosity altogether is called “matrix”.

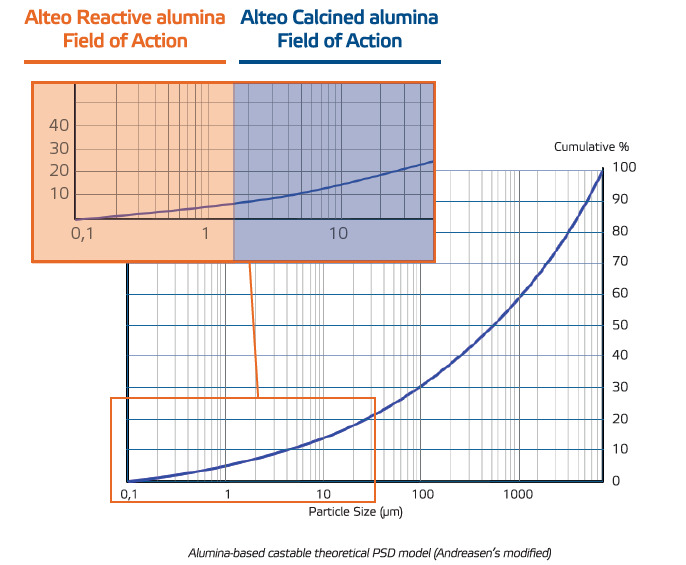

The aggregates form the skeleton of the refractory material and provide the major part of the refractoriness, resistance to high temperature and resistance to corrosion and erosion. The matrix is composed of fine and ultra-fine materials (alumina, refractory cement, micro-silica,…). It will provide the material with its specific properties, notably by facilitating its installation or enhancing certain properties of the aggregates (refractoriness, resistance to abrasion,…).

The role of the matrix is therefore extremely important in achieving the performance of the material. Refractory material may take different forms according to its intended use: bricks castables, shotcrete, plastics, precast castables,… Each formulation must be adapted to reach the expected performances (installation and working life).

Alteo’s new range of aluminas, REal®, was developed to offer manufacturers of refractory materials:

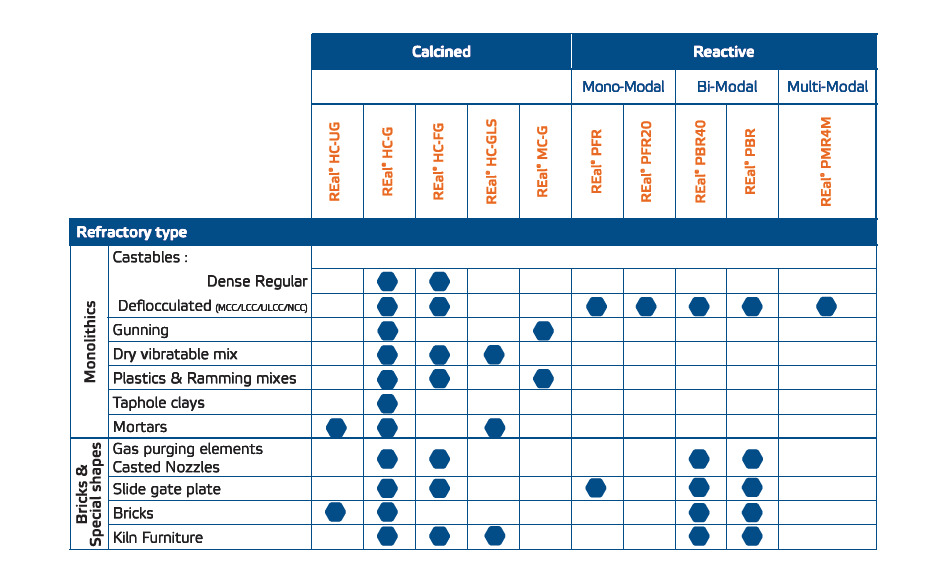

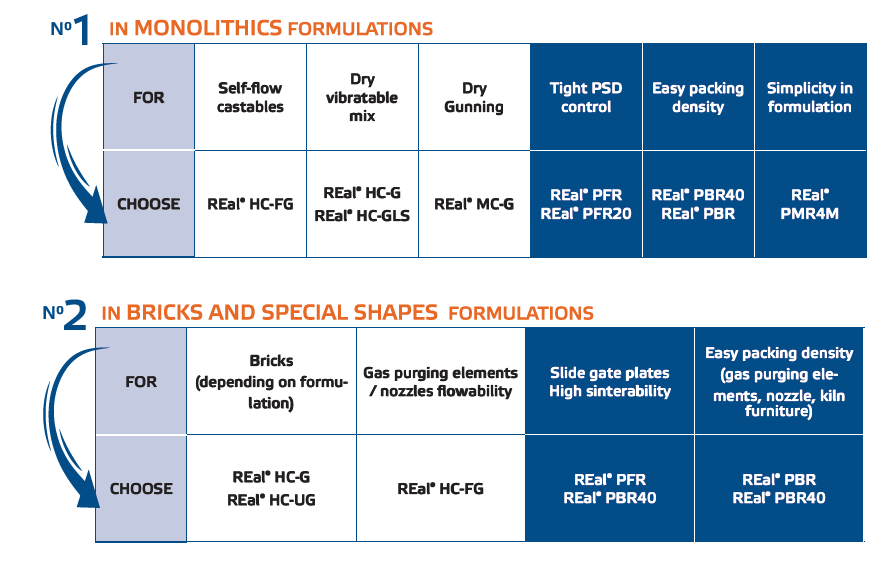

- Easier choice: specific products by application (monolithics, gunning, bricks and shapes)

- Improved performance levels: Alteo expertise and support to select the right alumina combination

- Easier management on your side: simplification for your teams by managing fewer references

- Stable and quality aluminas: tight specifications to guarantee the manufacturing of high performance refractories

Based on our expertise in the refractory field, you can select a REal® alumina for your application:

Our recommendation for your specific needs:

Discover all of our products in the new brochure.

Alteo

Alteo